At first glance, the idea of creating a flatbed scanner with an optical resolution of more than 600 ppi, not designed to work with transparent originals, seems rather doubtful - after all, for the vast majority of originals scanned in reflected light, more than 300-400 ppi is enough. However, do not forget that a large proportion of the originals scanned both at home and in the office are images printed in a typographical way. Due to the interference phenomena that occur when digitizing rasterized images, a noticeable moiré appears on the resulting image, which is quite difficult to deal with without compromising the quality or size of the image. To combat such phenomena, special algorithms are used, embedded in the scanning control programs. Typically, moiré reduction is based on scanning the original at an oversized (i.e., higher than user-specified) resolution and then software processing received image. This is where the advantage of higher resolution scanners will be obvious in the truest sense of the word.

Main technical parameters of scanners

Resolution

Resolution, or resolution, is one of the most important parameters that characterize the capabilities of a scanner. The most common unit for measuring the resolution of scanners is number of pixels per inch (pixels per inch, ppi). Ppi should not be identified with a more well-known unit dpi (dots per inch- the number of dots per inch), which is used to measure the resolution of raster printing devices and has a slightly different meaning.

Distinguish optical and interpolated permission. The optical resolution value can be calculated by dividing the number of photosensitive elements in the scanning bar by the plate width. It is easy to calculate that the number of light-sensitive elements in the scanners we are considering, which have an optical resolution of 1200 ppi and a Legal tablet format (that is, a width of 8.5 inches, or 216 mm), should be at least 11 thousand.

Speaking of a scanner as an abstract digital device, you need to understand that optical resolution is sampling frequency, only in this case The countdown is not based on time, but on distance.

In table. 1 shows the required resolution values for solving the most common tasks. As you can see, when scanning in reflected light, a resolution of 300 ppi is sufficient in most cases, and higher values \u200b\u200bare required either for scaling the original to a larger size, or for working with transparent originals, in particular 35 mm transparencies and negatives.

Table 1. Resolution values for solving the most common problems

|

Application |

Required resolution, ppi |

|---|---|

Scanning in reflected light |

|

|

Illustrations for web pages |

|

|

Text recognising |

|

|

Line art for printing on a monochrome printer |

|

|

Black and white photo for printing on a monochrome printer |

|

|

Color photo for printing on an inkjet printer |

|

|

Text and graphics for faxing |

|

|

Color photo for offset printing |

|

Scanning in transmitted light |

|

|

35mm film, photo for web pages |

|

|

35mm film, inkjet printable photo |

|

|

60mm film, photo for web pages |

|

|

60mm film, inkjet printable photo |

|

Many manufacturers, in an effort to attract customers, indicate in the documentation and on the boxes of their products the value of the optical resolution of 1200 * 2400 ppi. However, twice the number for the vertical axis means nothing more than scanning with half the vertical step and further software interpolation, so in this case the optical resolution of these models actually remains equal to the first digit.

Interpolated resolution is the increase in the number of pixels in a scanned image through software processing. The value of the interpolated resolution can be many times greater than the value of the optical resolution, however, it should be remembered that the amount of information obtained from the original will be the same as when scanning at optical resolution. In other words, you won't be able to enhance image detail when scanning at a resolution higher than optical.

Bit depth

Bit depth, or color depth, determines the maximum number of values that a pixel's color can take. In other words, the higher the bit depth during scanning, the large quantity shades may contain the resulting image. For example, when scanning a black and white image with a bit depth of 8 bits, we can get 256 gray levels (2 8 = 256), and using 10 bits - already 1024 gradations (2 10 = 1024). For color images, there are two options for the specified bit depth - the number of bits for each of the basic colors or the total number of bits. The current standard for storing and transmitting full-color images (such as photographs) is 24-bit color. Since when scanning color originals, the image is formed according to the additive principle from three basic colors, each of them has 8 bits, and the number of possible shades is a little more than 16.7 million (2 24 = 16 777 216). Many scanners use a large bit depth - 12, 14 or 16 bits per color (full bit depth is 36, 42 or 48 bits, respectively), however, for recording and further processing of images, this function must be supported by the software used; otherwise, the resulting image will be written to a 24-bit file.

It should be noted that a higher bit depth does not always mean a higher image quality. When specifying 36- or 48-bit color depth in documentation or promotional materials, manufacturers often keep silent about the fact that some of the bits are used to store service information.

Dynamic range (maximum optical density)

As you know, darker areas of the image absorb more light falling on them than light ones. The optical density value indicates how dark a given area of the image is and, therefore, how much light is absorbed and how much is reflected (or transmitted through in the case of a transparent original). Density is usually measured for some standard light source having a predetermined spectrum. The density value is calculated by the formula:

where D is the density value, R is the reflectance (that is, the proportion of reflected or transmitted light).

For example, for an area of the original that reflects (transmits) 15% of the light incident on it, the density value will be log(1/0.15) = 0.8239.

The higher the maximum perceived density, the more dynamic range this device. Theoretically, the dynamic range is limited by the bit depth used. So, an eight-bit monochrome image can have up to 256 gradations, that is, the minimum reproduced hue will be 1/256 (0.39%), therefore the dynamic range will be equal to log (256) = 2.4. For a 10-bit image, it will already be a little more than 3, and for a 12-bit image, it will be 3.61.

In effect, this means that a scanner with a higher dynamic range can better reproduce dark parts of images or simply dark images (such as overexposed photographs). It should be noted that in real conditions the dynamic range is less than the above values due to the influence of noise and crosstalk.

In most cases, the density of opaque originals scanned for reflection does not exceed 2.0 (corresponding to an area with 1% reflection), while a typical value for high-quality printed originals is 1.6. Slides and negatives may have areas above 2.0 density.

Light source

The light source used in the design of a particular scanner, to a large extent affects the quality of the resulting image. Four types of light sources are currently in use:

- Xenon discharge lamps . They are characterized by extremely short on-time, high radiation stability, small size and long service life. But they are not very efficient in terms of the ratio of the amount of energy consumed and the intensity of the luminous flux, they have a non-ideal spectrum (which can cause a violation of color accuracy) and require high voltage (about 2 kV).

- Hot cathode fluorescent lamps. These lamps have the highest efficiency, a very even spectrum (which, moreover, can be controlled within certain limits) and a short warm-up time (about 3-5 s). The negative aspects include not very stable characteristics, rather large dimensions, a relatively short service life (about 1000 hours) and the need to keep the lamp constantly on during the scanner operation.

- Cold cathode fluorescent lamps. Such lamps have a very long service life (from 5 to 10 thousand hours), low operating temperature, and an even spectrum (it should be noted that the design of some models of these lamps is optimized to increase the intensity of the light flux, which negatively affects the spectral characteristics). These advantages come at the cost of a rather long warm-up time (from 30 s to several minutes) and higher energy consumption than hot cathode lamps.

- Light emitting diodes (LED). They are used, as a rule, in CIS-scanners. Color diodes have very small dimensions, low power consumption and do not require warm-up time. In many cases, three-color LEDs are used, which change the color of the emitted light at a high frequency. However, LEDs have a rather low (compared to lamps) light intensity, which reduces scanning speed and increases image noise. A very uneven and limited emission spectrum inevitably entails a deterioration in color reproduction.

Scanning speed and warm-up time

During testing, the time required for a cold start and recovery from power saving mode was measured.

To evaluate the performance of the tested scanners, measurements were taken of the time required to perform several of the most typical tasks. The countdown began from the moment you pressed the Scan button (or similar) in the application from which the scan was performed, and ended after this application was ready to work again (that is, it was possible to perform any actions, such as changing settings or scanning area).

Optical resolution - measured in dots per inch (dpi). A characteristic showing that the higher the resolution, the more information about the original can be entered into the computer and subjected to further processing. Often given such a characteristic as "interpolated resolution" (interpolation resolution). The value of this indicator is doubtful - this is a conditional resolution, up to which the scanner program "undertakes to count" the missing points. This parameter has nothing to do with the scanner mechanism and, if interpolation is still needed, then it is better to do it after scanning with a good graphics package.

Color depth

Color depth is a measure of the number of colors a scanner can recognize. Most computer applications, with the exception of professional graphics packages such as Photoshop, work with 24-bit color (16.77 million colors per dot). For scanners, this characteristic is usually higher - 30 bits, and, for the highest quality of flatbed scanners, - 36 bits or more. Of course, the question may arise - why would a scanner recognize more bits than it can transmit to a computer. However, not all received bits are equal. In scanners with CCD sensors, the top two bits of the theoretical color depth are usually “noise” and do not carry accurate color information. The most obvious consequence of "noisy" bits is not continuous, smooth transitions between adjacent gradations in digitized images. Accordingly, in a 36-bit scanner, the “noise” bits can be shifted far enough, and in the final digitized image there will be more pure tones per color channel.

Dynamic range (density range)

Optical density is a characteristic of the original, equal to the decimal logarithm of the ratio of light incident on the original to the light reflected (or transmitted - for transparent originals). The minimum possible value of 0.0 D is a perfectly white (transparent) original. A value of 4.0 D is a completely black (opaque) original. The dynamic range of the scanner characterizes what range of optical densities of the original the scanner can recognize without losing shades either in the highlights or in the shadows of the original. The maximum optical density of the scanner is the optical density of the original, which the scanner still distinguishes from complete darkness. All shades of the original darker than this border the scanner will not be able to distinguish. This value very well separates simple office scanners, which can lose detail, both in the dark and light areas of the slide, and, especially, the negative, from more professional models. As a rule, for most flatbed scanners, this value ranges from 1.7D (office models) to 3.4 D (semi-professional models). Most paper originals, whether photographs or magazine clippings, have an optical density of no more than 2.5D. Slides generally require a dynamic range of more than 2.7 D (Typically 3.0 - 3.8) for high-quality scanning. And only negatives and X-rays have higher densities (3.3D - 4.0D), and buying a scanner with a higher dynamic range makes sense if you will work mainly with them, otherwise you will simply overpay.

Kind of original. Scanning can be performed in transmitted light (for originals on a transparent substrate) or reflected light (for originals on an opaque substrate). Scanning negatives is particularly tricky because the process is not just about inverting color gradations from negative to positive. To accurately digitize color in negatives, the scanner must compensate for the color photographic veil on the original. There are several ways to solve this problem: hardware processing, software algorithms for switching from negative to positive, or lookup tables for specific types of photographic film.

optical resolution. The scanner does not capture the entire image, but line by line. A strip of photosensitive elements moves along the vertical of the flatbed scanner and captures the image point by point line by line. The more photosensitive elements the scanner has, the more points it can take from each horizontal bar Images. This is called optical resolution. Usually it is considered by the number of dots per inch - dpi (dots per inch). Today, a resolution level of at least 600 dpi is considered the norm.

Work speed. Unlike printers, the speed of scanners is rarely indicated, since it depends on many factors. Sometimes they indicate the scanning speed of one line in milliseconds.

Color depth measured by the number of shades that the device is able to recognize. 24 bits corresponds to 16,777,216 shades. Modern scanners are produced with a color depth of 24, 30, 36, 48 bits.

Dynamic Range characterizes what range of optical densities of the original the scanner can recognize without losing shades either in the highlights or in the shadows of the original. The maximum optical density of the scanner is the optical density of the original, which the scanner still distinguishes from complete darkness. All shades of the original darker than this border the scanner will not be able to distinguish.

Batch processing - is scanning multiple originals at the same time, saving each image to separate file. Program batch processing allows you to scan a certain number of originals without operator intervention, providing automatic switching scan modes and saving scanned files.

Zoom range - is the range of original zoom values that can be performed during scanning. It is related to the resolution of the scanner: the higher the value of the maximum optical resolution, the greater the magnification factor of the original image without loss of quality.

By interface type Scanners fall into just four categories:

Parallel or serial scanners connected to LPT or COM port These interfaces are the slowest. There may be problems associated with a conflict between the scanner and the LPT printer, if any.

Scanners with USB interface Cost a little more, but work much faster. A computer with a USB port is required.

Scanners with a SCSI interface, with their own interface card for the ISA or PCI bus, or connected to a standard SCSI controller. These scanners are faster and more expensive than the representatives of the two previous categories and belong to a higher class.

Scanners with modern interface FireWire(IEEE 1394) specially designed for graphics and video. Such models are presented on the market relatively recently.

Results:

- The scanner is able to perceive normally, almost without distortion, the density of a transparent original up to 1.6

- The scanner, introducing distortions and "noises", but still able to perceive densities from 1.6 before 2.35

- The scanner is blind to density 2.4 , it perceives any density above this value as black.

What to do?

Let's see what the scanner manufacturer offers us. In Xsane (to be precise, in the backend "e Sane) it is possible to adjust the brightness using the "iron". That is, the scanner, as it were, increases the brightness of the lamp in order to "pierce" D max= 2.4 . In fact, there is no increase in the brightness of the lamp, the scanner (or rather its firmware) processes the received values, as a result we should get a higher maximum density value, which the scanner interprets as black. So, we will use the capabilities provided by the manufacturer. Set the Brightness value in Xsane to the maximum that the hardware allows. In our case, this 3 .

As in the previous test, we build a graph based on the results obtained (in order not to overload the reader with information, I do not give them).

For comparison, the first characteristic curve (test 1 ) was left, the new curve (Brightness= 3

) is marked in red (test 2 ). Let's start a comparative analysis: the scanner as it had ΔD scanner = 2.4

it has, on the basis of which it can be judged that the "decibel" (signal amplification mode) is always on, and works on the site D test= 1.6

D test= 2.4

, since no new, higher values D max_test can't be distinguished by the scanner.

Characteristic broken line on the plot D test= 1.6-2.4 became smooth, which indicates that the scanner firmware, when the option to increase brightness, converts the values received from the matrix more correctly in terms of tone transfer. But judging by the images, the “noise” does not become less from this, they only become more, as they are strengthened, or, perhaps, the “noise” becomes more even. Most likely the latter is true.

Now let's look at the area from D test= 0.0 before D test= 0.5 , the curve in this section has a low gamma value. That is, the lights will be transmitted softly, and lighter than they actually are.

Let's evaluate the result as a whole: the increase in brightness occurs not due to the effective use of densities, but due to a change in the level of all densities (pay attention to what tone the “black” value is transmitted if in test1 it is at the value D scanner = 1.4 , then in test2 on the value D scanner = 1.2 ). There is no point in using this option. We will not get any useful increase in brightness. The "gray field" will become lighter; the "white field" will remain the same as it was; The "black field" will also become lighter, but no new details will appear there. Scanner as "seen" D scanner = 2.4 , and "sees". But the level of "noise" will increase.

To be honest, when I did this test, I thought that Epson would still “shift” the curve to the right, i.e. we will lose details in the highlights, but we will gain in the shadows, i.e. D scanner will not change, but will work on a different site D test =( D max- D min). Perhaps the manufacturer tried to implement this feature. This is indicated by the characteristic curve in the range D test 0.0-0.5

. I will assume that this is done in order not to lose details in the highlights in case the curve shifts to the right. In practice, only the average gradient has decreased.

Scanning black and white negatives.

Let us try to prove the obtained results in practice. For the "purity" of the experiment, I will always use one single black and white negative. I note that the negative used has normal densities, and is also developed to a medium gradient 0.62 which is the de facto standard. In the cinema laboratory, it is printed on the 11th light, which is the norm.

As we have already found out, one of the problems with scanning both negatives and slides is the presence of "noise" in the image. This phenomenon is especially noticeable when scanning rather dense (dark) originals. This is due to the limited range of optical densities ΔD scanner= D max -D min.

For example: the Nikon Coolscan 4000 scanner is capable of reproducing a range of optical densities 4.2 (so I don’t want to upset anyone ... about Epson 1650, I already figured it out ΔD=3.0 :-)). Simpler scanners have more modest performance.

Maximum range of optical densities of b/w negative 2.5 , ΔD max slide = 3.0 , color masked negative approx. 2.5 , but due to the presence of a mask, this type of negatives has a large D min.

I am convinced that ΔD scanner = 3.0 enough to scan anything, except, perhaps, x-rays. The problem is, on what part of the negative (slide) is this ΔD scanner = 3.0 . I'll try to explain why.

Tikhon Baranov

Desktop scanners appeared in the 80s and immediately became the object of increased attention, but the complexity of use, the lack of a universal software, and most importantly, the high price did not allow scanners to go beyond specialized use.

Not much time has passed since then, but a whole line of desktop scanners has already emerged, designed mainly for office and home use. Moreover, over the past few years, thanks to the incredible price reduction, the popularity of scanners has grown significantly. The price of a good flatbed scanner today is commensurate with the price of a good video card or printer, so it is logical to continue buying a computer and printer by purchasing a scanner.

Last two years flatbed scanners the price has fallen so much, and the range of models offered has grown so much that the choice of this device for specific tasks has become more than relevant.

In the proposed material, I would like to talk about the structure of a flatbed scanner, analyze the features of the scanning process and give some recommendations on purchasing a flatbed scanner.

A desktop scanner is indispensable when working with a computer if you need to insert graphic images or texts from paper media into documents created using a computer. Modern desktop scanners are quite easy to use, have an intuitive interface, but there are a number of characteristics and features that you should pay attention to when choosing a scanner - the optical system, the software part of the TWAIN module and the interface. Let's analyze all three parts separately.

Optics and mechanics

This part consists of a scanning carriage with a light source, a focusing objective or lens, a charge-coupled device, and an analog-to-digital converter (ADC).

Actually the whole scanning process involving all of the above is as follows. On the transparent glass under the cover of the scanner is placed the image (text, graphics, photograph) to be scanned, "face" down. Then the carriage begins to move, making a path equal to the length of the glass. A cold cathode lamp located on it illuminates the image. Using a focusing lens, the light flux from the image is projected onto a charge-coupled device, where it is converted into analog information. The latter in the ADC becomes digital, i.e. bitwise, and thus understandable to a computer. A similar analog-to-digital (and vice versa) conversion is performed by a modem, since information is transmitted over telephone lines in analog form.

Accurate color reproduction when scanning color images occurs by dividing the scanned color into three main components - colors: red, green and blue.

Here I would like to say a few words about the concept of "color depth", because if color information is stored in bits, then the color depth is a certain number of bits. Standard ("true") can be considered a color depth of 24 bits per point, when RGB colors have 8 bits. Accordingly, with such a bit depth, the scanner perceives 16.77 million color shades of one point. In addition to 24-bit scanners, 30-, 36-, 42- and even 48-bit scanners are widely used today. But what's interesting: the human eye is "not designed" for a color depth of more than 24 bits. The increase in the bit depth of scanners is caused by the unwillingness of manufacturers to earn extra money on the hysteria around technological races, the reason is different: analog-to-digital conversion leads to distortion in the lower, most "vulnerable" bits - 30-bit (and higher) systems do not pass empty information into computer, "pulling out" the output color depth to full 24 bits.

In the past, you had to use three-pass technology for color scanning. That is, the first pass with a red filter to obtain the red component, the second - for the green component and the third = - for the blue. This method has two significant drawbacks: low speed and the problem of combining three separate scans into one, resulting in color mismatch.

The solution was the creation of True Color CCD, allowing to perceive all three color components of a color image in one pass. True Color CCD is the standard on this moment and no one in the world produces three-pass scanners anymore. Similarly, black-and-white flatbed scanners ceased to exist at one time.

The average user may be confused by the variety various resolutions offered by the manufacturer. This concept can be divided into two groups:

- Optical Resolution

It is determined by the number of cells in the matrix line divided by the width of the scan field. Typically, the scanner resolution is indicated by two numbers: 300x600 ppi, 600x1200 ppi, etc. I would like the reader to pay attention that the designation ppi (pixels per inch - pixels per inch) is more accurate in relation to the scan resolution, in relation to the image printed on the printer - dpi (dots per inch - dots per inch).

- Interpolated Resolution

Selected by the user and may be several times higher than the actual resolution of the scanner. For example, a 600 ppi software resolution on an HP ScanJet 5100C scanner can be scaled up to 1200 ppi. However, more does not mean better in this case. High-quality scanning is obtained at a resolution equal to optical, or less, but a multiple of it. This characteristic is very much loved by manufacturers of desktop scanners, often included in the name and applied in large letters on a colorful box. You may see 4800, 9600 etc.

When buying a scanner, it should be understood that the general approach to computer technology"more is better" (memory, CPU speed, etc.) does not generally apply to scanners. That is, of course, better and of course more expensive, but you may never need it! The resolution you need to use when scanning is determined by the output device you are using.

When scanning images, it is necessary to build on the optical resolution of the scanner. Those. if the scanner resolution is set to 300x600 ppi, scan at 300x300 ppi or 150x150 ppi. Files with interpolated resolution (in this case it can be 600, 1200, 2400 or more ppi) are not only large in volume, but also contain many unrealistic, programmatically "invented" pixels, which affects the quality of the resulting image.

For one-to-one display (presentations, web design) it is sufficient to set 72 dpi or 100 dpi, since all monitors output either 72 or 96 dpi.

When using an inkjet printer, when outputting color images, it is enough to set the scanner resolution = printer resolution / 3, as printer manufacturers indicate maximum resolution printers, when printing in color inkjet printers use three points to create one point received from the scanner. That is, here you will have enough 200 - 250 dpi.

Then in what cases should high resolution? The answer is simple: if you want to enlarge or stretch the image taken from the original. Think about it: maybe you will never have such a need, but you will have to overpay a lot.

One of the main characteristics of a scanner is its dynamic range. Let's explain this feature a bit. Any image has an optical density: from 0.0 D (absolutely white, transparent) to 4.0 (absolutely black, opaque). The dynamic range of a scanner is determined by its ability to perceive the optical density of the scanned image. If the scanner has a dynamic range of 2.5 D, then it will be able to handle photographs, but will fail when working with negatives that have an optical density of more than 3.0 D. This means that the scanner will not perceive the darkest parts of the image and will produce incomplete scan. To make it clear, I will give, as an example, Soviet color film. Those who dealt with it will understand the comparison perfectly. Soviet film was produced with a low color depth and therefore had big problems with displaying light and dark tones.

Cheap flatbed scanners have a dynamic range of 2.0 - 2.7D, good 3.0 = - 3.3D, latest models 3.6d.

One of the most important parameters of the matrix is the level of noise produced by it. High level"noisy" extremely negatively affects the quality of scanning, reducing the dynamic range and the number of bits with really useful data. Permissible noise level of CCD matrices of SOHO sector scanners is 3-4mV.

In this article the author tries to give some overview of scanners with traditional CCD technology. In fairness, it must be said that there is an alternative on the market - CIS technology. The latter has been known for a long time, but scanners using this technology have appeared relatively recently. In such scanners, optics and mirrors are completely absent, the receiving element is equal in width to the working scanning field and is a line of several identical matrices. In addition to other relatively minor drawbacks, this option has two fundamental ones: poor focusing (no optics) and small gaps between adjacent matrices. This does not interfere with text scanning, but to work with full-color graphics it is better to choose a scanner built on the basis of traditional CCD technology.

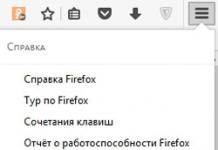

TWAIN module

Paradoxically, but true: the scanner is not a standard device for Windows. (One could dispute this statement, because Windows`98 drivers for scanners are installed. However, I have not yet come across a scanner that would work with "ninety-eight" drivers. Maybe because the drivers are written for USB, and scanners with such there are still few interfaces on the market.) special program, which is the TWAIN module. It does not represent anything particularly complicated, but one must take into account the fact that different versions of the TWAIN module from the same manufacturer may behave inappropriately with respect to different versions Windows, up to their complete incompatibility. This can be easily understood if we take into account the similarity of the TWAIN module with an ordinary driver that needs to be updated, for example, with the release of a new "brainchild" of Bill Gates. Actually, thanks to the TWAIN module, the user is able to control the scanning process on the monitor screen. These modules, like "works of art" of specific scanner manufacturers, are distinguished by a different set of their functionality. In the modules of inexpensive color tablets, most likely, the user will find functions such as: window preview, automatic detection of the scanning area, the ability to select the resolution and scanning mode, adjusting the contrast, brightness and gamma, the filter for suppressing the printed raster, etc. In addition to the above, there are many other, more specific, functions - they can be found in the modules of professional scanners, call them here we will not.

Hardware interface

The interface affects the speed of the scanning process being responsible for the speed of data exchange between the computer and the scanner. Now LPT- and SCSI-scanners have been supplemented with models equipped with a promising and nimble USB interface. For example, there are three versions of the Astra 1220 model (manufactured by UMAX): Astra 1220P connected to the printer port, Astra 1220U using the USB interface, and Astra 1220S = - SCSI device. The fastest of them is the model with SCSI interface, with USB - slower, and with LPT - the most "low-speed". In general, the SCSI/USB/LPT ratio is considered to be 3/2/1. At the same time, it should be noted that in individual cases the speed performance of scanners with one or another interface may differ significantly from what is expected. However, such moments only confirm the rule, so the difference in price between LPT-, USB- and SCSI-scanners is quite justified.

However, there are a number of conditions that may slightly speed up the operation of your scanner's interface devices.

There are cases when a conflict between two SCSI controllers led to a significant slowdown of the scanner. If this problem cannot be solved by reassigning resources to conflicting devices, consider installing the scanner as part of a SCSI chain on a more powerful controller. In this case, the scanner must be latest device chain, it should be terminated, and the SCSI ID should be set to the position corresponding to the requirements of the controller used (admissible positions: 1...6). The experience of using Mustek scanners with fast Adaptec 2940 AU and Asus SC-200 PCI controllers shows that the scanner connected in this way works faster than with the "native" SCSI-II card DTC3181.

Scanner selection

First of all, I want the buyer to keep in mind that the scanner is always bought for specific jobs, and do not try to twist your fingers here in front of your friends, showing them the model that you have purchased, well, with very cool features - an experienced, knowledgeable user can over you laugh. If you have no idea what kind of work you will be doing, then you most likely need a scanner for your home, and below we will select a scanner for you.

Text scanning works

Any scanners are suitable for these works, since black and white text can be scanned well by almost any of the scanners on the market - feel free to choose the most cheap option one of the famous manufacturers.

homework

If you don’t set yourself global, large-scale tasks and you don’t have some kind of “super-duper-color laser” printer nearby, with “drop-dead” characteristics, with which you quietly intend to do what our factory does Goznak, then Mustek's Scan Express series will suit you, at the lowest price it will give you quite acceptable quality. To view images on a monitor, a scanner resolution of 100 dpi is enough for you; for printing on a printer with a small increase, 600 dpi is enough. If you are going to create a huge home photo archive, then you should pay attention to more powerful models - the Mustek Paragon series, designed for large volumes of work, and Umax Astra scanners with improved color reproduction, for those who are familiar with PhotoShop firsthand and can calibrate their monitor at a simple level.

If you are not familiar with internal device computer - choose scanners with a parallel port connection - they are a little slower, but easier to install. If you are lucky, and you = the owner of a computer of the last year of manufacture with a USB bus, then a scanner on a USB v port will be more preferable for you - it is faster than a scanner on an LPT. For those who are not afraid to install a SCSI card themselves, scanners with a SCSI interface are best suited.

office work

Scanners for the office should be designed for a large amount of work and render colors better, since offices tend to have higher quality color printers. The scanner should allow you to connect a slide adapter, it is also desirable to connect an automatic document feeder. For such work, the Paragon Mustek series is suitable, such as scanners entry level. To create and print your own colorful flyers and presentations, you need scanners with better color reproduction - Umax Astra and Agfa Snap-Scan (AGFA scanners provide more opportunities for a trained operator). The most powerful scanner in this class is Umax Astra 2400S Plus, designed for large volumes of work.

Hewlett-Packard scanners have gained quite a lot of popularity both all over the world and in our market. For the most part, they are in various offices in our country, having quite good intercity services and repair and maintenance workshops. The most popular models for office work can be considered ScanJet 5200C and ScanJet 6200C

Scanners for advertising agencies

The main tasks for these scanners are high-quality scanning of small volumes of slides and paper originals. The scanner must have high resolution(You will need 1200 dpi to scan your slides for printing at 10x15 cm (standard photo format) and 2400 dpi to print your slide to A4) and good dynamic range . (Scanning photographs requires a range of 2.3D, slides require a range of optical densities greater than 2.8-3.0 D, and negatives greater than 3.3 D.) The cheapest scanners in this class are Agfa Duoscan T1200 with excellent quality, but low resolution 600x1200 dpi, and Mustek Paragon Power Pro with good resolution 1200x2400 dpi, but with a low dynamic range - for companies that cannot afford significant financial costs. For more demanding users, AGFA Duoscan and Umax PowerLook III, HP ScanJet 6350C scanners with good color reproduction and dynamic range (3.4D) and high resolution (1000x2000 and 1200x2400, respectively) are suitable.

Scanning a large number of slides

To scan large volumes of slides, scanners with the same characteristics as the previous group are needed, but in a larger format - A3. On the glass of such a scanner there are several slides at once, which are scanned in batch mode. If you do not need a high resolution scanner, then the Mirage IIse scanner is the ideal choice for you in this group. Scanner AGFA Duoscan T2000XL with a high resolution of 2000x2000 dpi will suit you if you need to enlarge the scanned slides to a format close to A4. Hewlett-Packard also has a fairly good offer on the market for this type of work, which presents its model on the market - Photo Scanner S20, which, according to the author, is well optimized for working with 35 mm negatives.

Scanning large format slides

Scanning of x-rays, flaw detection materials and aerial photography. Here are scanners with low resolution, but with good quality color reproduction and high dynamic range. These are Mustek Paragon A3 Pro with a resolution of 600x1200 and Umax Mirage IIse with a resolution of 700x1400 dpi.

Scanners for Polygraphy

For these tasks, scanners must be of the highest quality, and the choice of scanner should be determined to a large extent by the price you are willing to spend on it. The simplest scanner in this category is the AGFA Duoscan T2500 with a resolution of 2500 dpi. A more powerful Umax PowerLook 3000 model with a resolution of 3048x3048. And two models of AGFA A3 format - AgfaScan 5000 with a resolution of 2500x5000 and AgfaScan XY-15 with a resolution of 5000x5000 in full A3 + format.

Finally, I would like to give some advice when buying this device:

And one more thing: when transporting the scanner, do not forget to put a special plug in the closed mode, otherwise you will drive between the service center and the house.

Here, it seems, for the first time and all. And the last thing: one of my acquaintances has accumulated at home a bunch of different computer hardware - video cards, processors, sound cards - he sold it and bought himself scanners. Dear reader, take a look in your pantry, maybe there is your unpurchased scanner. So think, decide, search! The choice is yours.

|